FRONT PANEL SCREEN PRINTING, AN ALLIANCE BETWEEN AESTHETICS AND FUNCTIONALITY

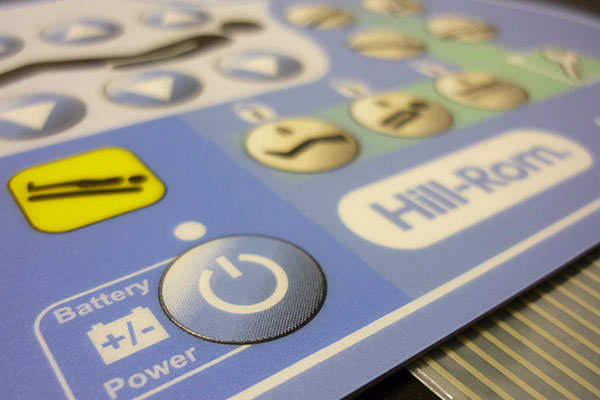

The industrial, medical equipment, heating/air-conditioning devices and electrical tooling are often fitted with screen printed front panels with a display interface to facilitate and make their use more comfortable.

To always vary, the supple front panels must answer a demanding design and functional, ergonomic imperatives, while remaining ultra-resistant for use.

You are manufacturing industrial or domestic equipment and your front panel screen printings must be attractive, of impeccable quality, reliable and conform to the look of your products. For you, DB TECHNIQUE uses its tested expertise to answer your targets.

Whether it be active or inactive interfaces, our expertise in that field is supported by the renewed trust of referent groups in their field, which we help in developing new products.

To exchange on your front panel project, click here right now, a professional will call you back as soon as today.

Lexan printing for active or inactive interfaces

The active front panel, also called IHM (Interface Homme Machine), is an interface between the electronic part of some device and its user. It must have an ergonomic design, be easy to use and match the design of the equipment.

The non-active front panel can also be assimilated to a decoration front panel integrating or not visual display windows.

The choice of the material combined with subsurface printing guarantees an exceptional resistance, whatever the conditions of use (cleaning products, humidity, UV…).

High quality customization of your products with the industrial marking; variations of ranges are possible with a better flexibility and optimized costs, in comparison with a direct marking

Our technical expertise

Our plus that make the difference

Our collaborators’ expertise can be appreciated along the manufacturing process: